Not all Biochar is Created Equal

Imagine if Biochar could be embedded in:

You don’t have to imagine for long - our technology is re-defining biochar’s applications.

Every year, vast quantities of biomass waste decompose or are burned, releasing their carbon back into the atmosphere. ITER’s technology changes that equation. Our advanced pyrolysis reactors convert these residues into clean, stable biocarbon, capturing CO2 in solid form instead of letting it escape.

This makes ITER biocarbon a powerful Negative Emissions Technology (NET). When incorporated into long-lived carbon sinks such as soils, construction materials, composites, or asphalt, it provides durable, long-term CO2 storage measured in centuries to millennia.

Our process produces biocarbon of exceptional purity, free from pollutants and suitable for a diverse portfolio of uses. With tunable processing stages, ITER enables products ranging from regenerative agriculture amendments to specialty industrial carbons for filtration, manufacturing, and advanced materials.

Biochar Applications

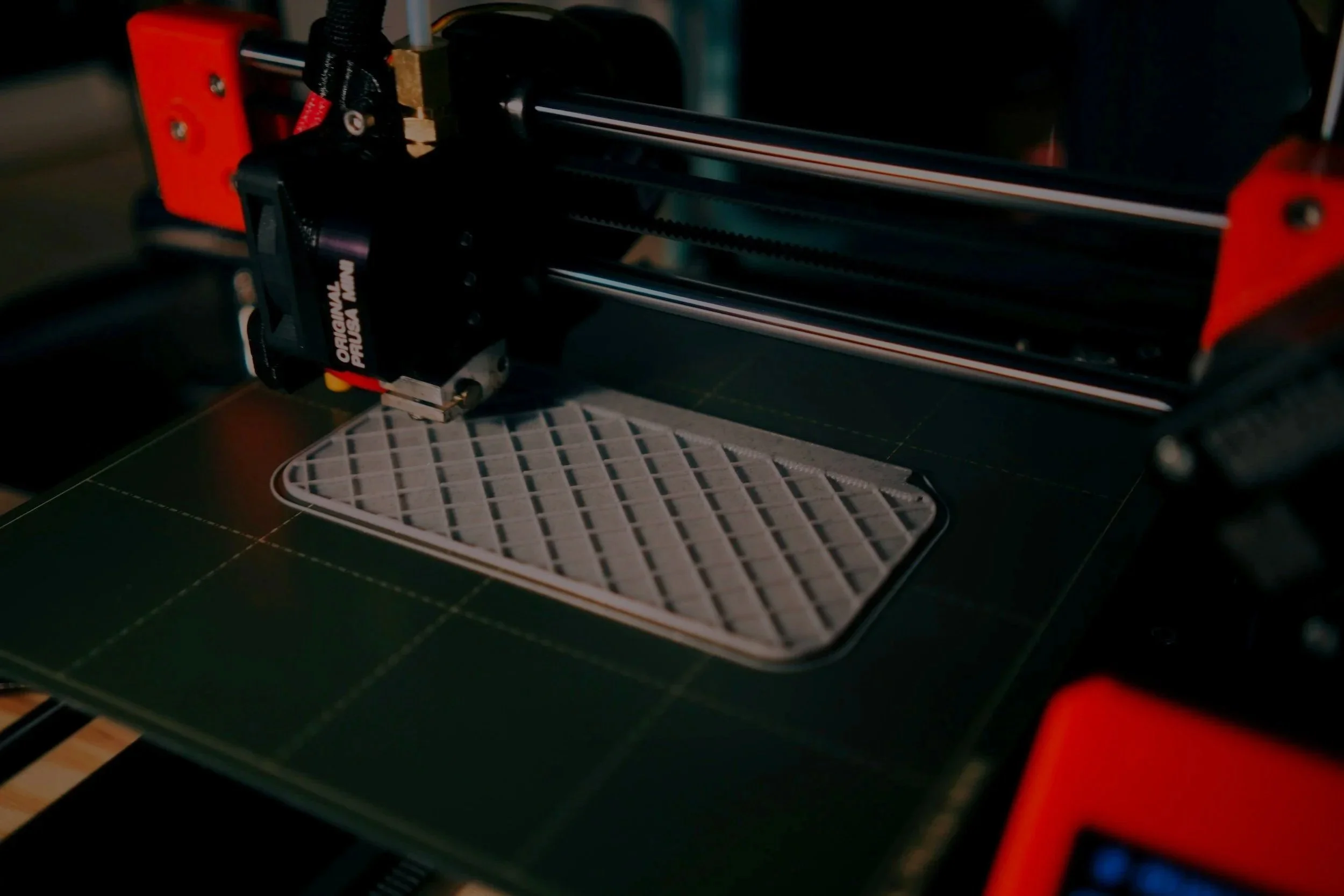

How It’s Made

Biochar is a carbon-rich material produced by the pyrolysis of organic residues such as wood chips, crop waste, and other biomass. Pyrolysis involves heating this material to 400–800 °C in the absence of oxygen, causing the biomass to decompose into gases, vapors, and a stable carbon matrix. As temperature and severity increase, more volatiles and impurities are driven off, leaving behind purer, more structurally refined carbon.

However, not all pyrolysis conditions are created equal. There is a significant difference between slowly heating biomass from room temperature and introducing it directly into a reactor already at operating temperature (e.g., 600 °C). Under the latter conditions, the material undergoes an intense and instantaneous devolatilization - almost like popcorn bursting - rapidly expelling internal vapors. This “popping” effect cleans out internal pores, increases surface area, and produces a higher-value, cleaner carbon product.

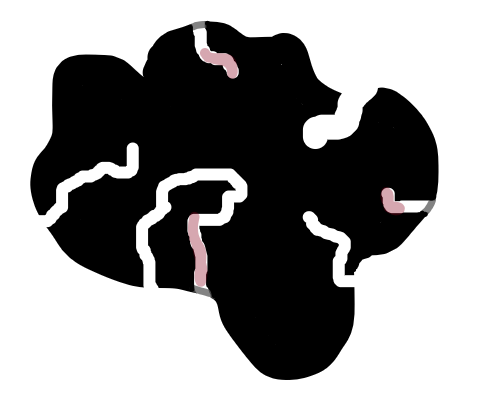

Partially unreacted particle: pores are not fully developed, some are clogged and still contain contaminants

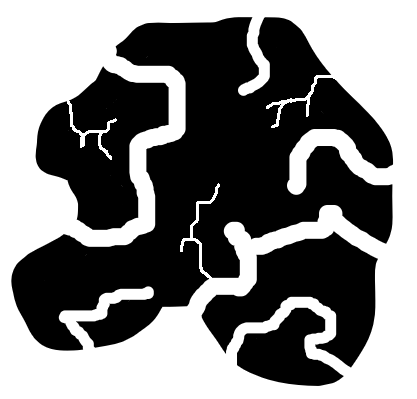

Fully reacted particle: greater pore network developed and free of contaminants.

The Problem We’re Solving

Conventional auger-fed and rotary kiln reactors cannot achieve this “popcorn” effect. Their long heat-up zones, uneven temperature profiles, and limited mixing prevent biomass particles from experiencing the high-severity, uniform thermal shock required for complete impurity removal. Poor heat transfer and inconsistent residence times lead to partially carbonized material with lower purity and lower performance.

This is why ITER’s multi-stage design stands apart: it enables instantaneous heating, superior mixing, and unmatched heat transfer, creating the conditions necessary to produce truly high-purity biocarbon suitable for advanced industrial, agricultural, and environmental applications.

Biochars produced at various temperatures may all look similar, but chemically they are dramatically different. This is why it is critical to ensure carbon purity.

Our Biochar Achieves:

Surface Area > 300 m2/g

Carbon Content >90%

Volatile Content < 3%

This level of refinement opens the door to premium, regulation-sensitive markets traditionally inaccessible to conventional biochar technologies, including:

Food and feed applications requiring stringent contaminant limits

Pharmaceutical and cosmetic ingredients

Electronics and energy storage materials, where consistency and purity are critical

High-grade filtration and adsorption media

Advanced carbon materials for specialty industrial processes